Model: PJ-A3005D-50 Mitutoyo, Japan

| Specification | Learning Objective | Learning Outcome | Tools Required | Safety/Precaution |

|---|---|---|---|---|

| This is a multi-purpose Profile Projector | 1.Care & Operation | Understanding | Soft Lens Cleaning Cloth | Apron |

| for factory inspection use. It can perform | of Profile Projector | Operation of Profile | Soft Gloves | |

| precision measurement of work piece | 2. Magnification | Projector | Lens Cleaner | Shoes |

| dimension, contours and surface feature. | Requirement 3. Dimension & | Knowledge of | Magnifying Lens | |

| Code No. 302-704-1E (PJ-A3005D-50) | Angle Measuring | Dimension & Angle | ||

| X axis stroke 50mm, Y axis stroke 50mm | Techniques | Measuring Methods | Operation Guide Book | |

| Maximum Work Piece Height 123mm | 3. Result Analysis | Hands on Industrial | ||

| Magnification Error ± 0.1mm (in 100mm) | Experience | |||

| Magnification Error ± 0.14mm (in | For: | |||

| 140mm) | Diploma | Research and | ||

| B.Sc. / M.Sc. | Analysis | |||

| Resolution for coordinate measurement | B.Tech /M.Tech | |||

| (X, Y counter)-0.001mm | Research (PhD) |

PROFILE PROJECTOR PJ-A3000 SERIES

VOLATILE MATTER FURNACE

Model: VMF 10/6 Make: CARBOLITE Limited, UNITED KINGDOM| Specification | Learning Objective | Learning Outcome | Tools Required | Safety/Precaution |

|---|---|---|---|---|

| The VMF 10/6 designed for testing the | 1.Sample Preparation as per | Understand Volatile Matter in Coal | Grinder | Shoes |

| volatile matter of coal according to ISO | Standard | Pallet Press | Apron | |

| 562:2010 Maximum Temperature1000⁰C Type Front loading Maximum Continuous Operating Temperature 900⁰C Heat-up time 20 minutes to 900°C Dimensions: Internal H x W x D : ( mm) 100 x 210 x 260 Dimensions: External H x W x D (mm) 655 x 435 x 610 Max power (W) 3000 Thermocouple type K Make: CARBOLITE Limited, Parsons Lane, Hope, Hope Valley,533 6RB, UNITED KINGDOM GERO GmbH & Co. KG, Hesselbachstr,15, 75242 Neuhausen, GERMANY | 2.Care & Operation of Furnace & Accessories 3. Calculate Volatile Matter Percentage For: Diploma B.Sc. /M.Sc. B.Tech /M.Tech Research (PhD) | Evaluate Volatile Matter in Coal Write a Scientific & Professional Report for Volatile Matter in Coal Hands on Industrial Experience | Crucible Rack Plate Tong | Hand Gloves |

PROFILE PROJECTOR PJ-A3000 SERIES

ASHING FURNACE

Model: AAF 11/7 Make: CARBOLITE Limited, UNITED KINGDOM| Specification | Learning Objective | Learning Outcome | Tools Required | Safety/Precaution |

|---|---|---|---|---|

| The ash furnace provides optimum combustion | 1.Sample Preparation of | Understanding Ash Content in Coal | Grinder | Shoes |

| conditions to ensure complete combustion of | Coal for Ash Analysis as | Pallet Press | Apron | |

| the sample. The necessarily high airflow is | per Standard | Evaluate & Grading Coal (Ash | Crucible | Hand Gloves |

| preheated before entering the chamber. The silicon carbide tiles are provided to protect the heating elements from the accumulation of | 2.Operation & Care of Furnace 3.Grading & Reporting | Percentage) Write a Professional Scientific Report | Rack Plate Tong | |

| carbon that can occur during applications. Other heat treatment work can be done in AAF 11/7 furnace at a maximum operating temperature of 1100°C ± 5⁰C Make: CARBOLITE Limited, Parsons Lane, Hope, Hope Valley,533 6RB, UNITED KINGDOM GERO GmbH & Co. KG, Hesselbachstr,15, 75242 Neuhausen, GERMANY | Ash Content in Coal | Hands on Industrial Experience, |

ASHING FURNACE

ROCKWELL HARDNESS TESTING MACHINE -DIGITAL

Model: A300 (HR 320MS) Mitutoyo, Brazil| Specification | Learning Objective | Learning Outcome | Tools Required | Safety/Precaution |

|---|---|---|---|---|

| The Hardness Tester is designed to test the | 1.Sample | Safe Operation of | Weight: | Shoes |

| hardness of general steel, metals and some | Preparation | Hardness Tester | 15,30,45,60,100,150 grams | Apron |

| non metals to the Rockwell Hardness Test | 2.Operation of | Hand Gloves | ||

| Method using A, B, C scale. | Hardness Tester | Knowledge of | Diamond Indenter | |

| 3. Result Analysis | Hardness Scales | Steel Ball Indenter 1/6 inch | ||

| Make: Mitutoyo Sul Americana Ltda, Av, | Flat Anvil -64mm | |||

| Joao Carloos da Silva Borges,1240-CEP | Hands on Industrial | HRC Test Block-30 & | ||

| 04726-002 Santo Amaro- Sao Paulo-SP, | For: | Experience | 60HRC, 90HRB, 65HR30N, | |

| BRASIL | Diploma | & 70HR30T | ||

| B.Sc. / M.Sc. | Research and | AC Adapter | ||

| B.Tech /M.Tech Research (PhD) | Analysis |

ROCKWELL HARDNESS TESTING MACHINE -DIGITAL

ANALYTICAL SIEVE SHAKER

Model: AS 200 digital Retsch GmbH, Germany| Specification | Learning Objective | Learning Outcome | Tools Required | Safety/Precaution |

|---|---|---|---|---|

| AS 200 have digital time display, interval | 1.Standard Sample | Understand Grain Size & | 1. Vibration Deck | Shoes |

| operation and analogue adjustment with optical | Preparation | Mesh Size | 2. Sieve Sizes | Apron |

| monitoring of the vibration height. (vibration | 2.Arranging Sieves in a | 45µm | Hand Gloves | |

| height adjustable from 0 to 3mm). | Deck | Familiarization with ASTM | 65µm | |

| 3.Cleaning, Care & | & ISO Standards | 125µm | ||

| Electromagnetic drive | Operation of SIEVE | 250µm | ||

| 3 Dimensional Motion of Projections | SHAKER | Research & Development | 500µm | |

| 3000 Vibration / minute | 4. Result Analysis & | and Quality Control of Raw | 1.0mm | |

| Quiet Running (65 dB) | Report Writing | Materials | 2.0mm 4.0mm | |

| Application: | For: | Hands on Industrial | 3. Collecting Pan | |

| Separation, fractioning, | Diploma | Production Experience | 4. Wet pan | |

| Particle Size Determination | B.Sc. / M.Sc. | |||

| Feed material: Powders, Bulk Materials, | B.Tech /M.Tech | Independent Thinking | ||

| Slurry/Suspensions Measuring range: 20μm to 25mm Maximum Batch Feed Capacity: 3Kg Maximum No. of Fractions: 9/17 Maximum Mass of Sieve Stack: 4Kg Make: Retsch GmbH, Retsch-Alle 1-5, 42781 Haan,Germany | Research (PhD) |

ANALYTICAL SIEVE SHAKER

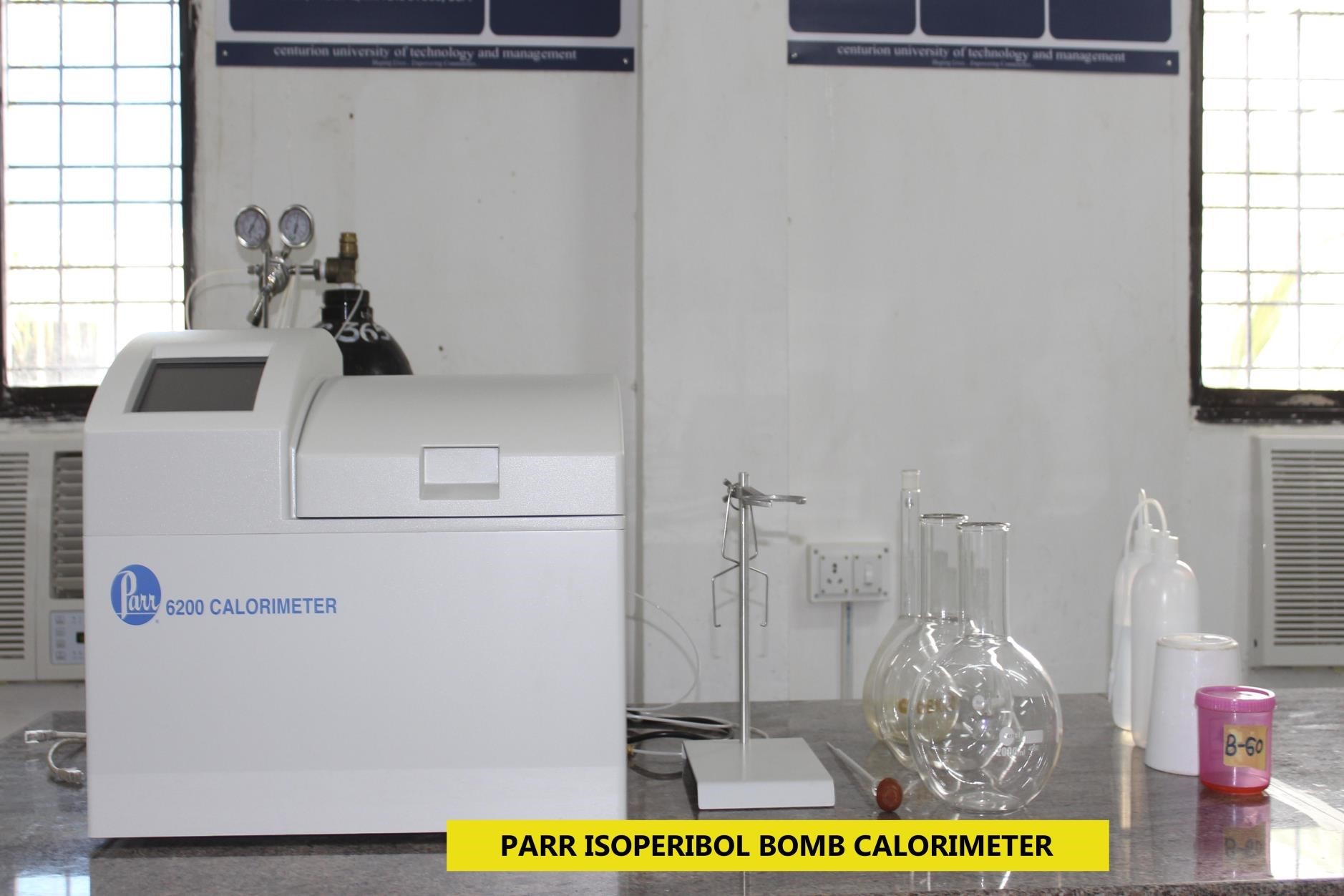

PARR ISOPERIBOL BOMB CALORIMETER

Model: 6200 with 1108P Vessel PARR INSTRUMENT COMPANY, USA| Specification | Learning Objective | Learning Outcome | Tools Required | Safety/Precaution |

|---|---|---|---|---|

| The temperature-controlled water | 1.Sample | Cleaning, Care & | 1108P Oxygen | Shoes |

| jacketed calorimeter with a built-in | Preparation (solid, | Operation of a Calorimeter | Combustion vessel | Apron |

| circulating system and an electric heater | liquid) | Oval Bucket – 1 No. | Hand | |

| calorimeter with Automatic | 2.Loading & | Test Procedure for | Ignition Thread test | Gloves |

| Microprocessor Control. It has a built-in | Operation | Calorific Value of a | Heat wire, | |

| automatic system for charging the | Procedure of | Substance | Benzoic acid pellets | |

| combustion vessel with oxygen. It is | Bomb Calorimeter | Sample crucibles – | ||

| equipped with high precision electronic | 3. Result Analysis | Understand & Evaluate | PK/6 | |

| thermometer. | Calorific Value | |||

| A variety of vessels can be used for testing | Oxygen Gas Cylinder | |||

| samples releasing from 52 calories to | For: | Write a Professional and | 47 Liters with Gas | |

| 12,000 calories per test. | Diploma B.Sc. / M.Sc. | Scientific Report | Regulator | |

| Test Hour: 4-7 as equipped | B.Tech /M.Tech | Hands on Industrial | ||

| Operator time per test: 6 min | Research (PhD) | Experience | ||

| Precision / Repeatability (%RSD): 0.05- 0.10% | Analytical and Critical | |||

| Temperature Resolution: 0.0001°C Removable Vessel & Bucket Bucket Filling: Manual Oxygen Filling: Automatic Combustion Vessel Washing: Manual Memory1000 Tests M/S. PARR INSTRUMENT COMPANY, 211, 53RD STREET, MOLINE, IIIINOIS 61265, USA | Thinking. |

PARR ISOPERIBOL BOMB CALORIMETER